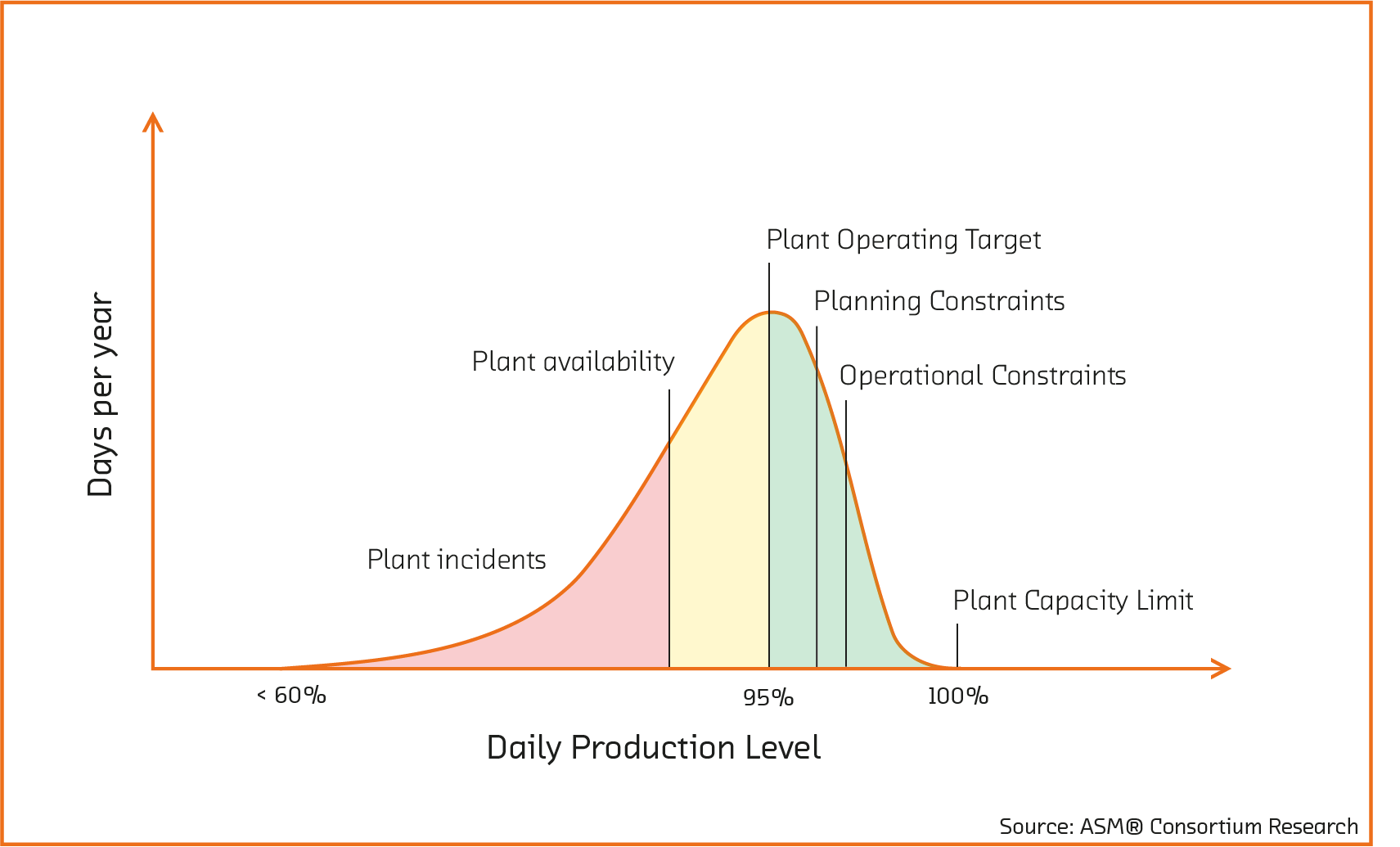

Industry studies show that industrial plants lose between 3-8 % of their production profit due to unplanned upsets or abnormal events.

To increase situational awareness in the control room, we have created a new product called the Control Room Assistant. The product helps operators find cause, consequences, and possible counteraction plans for abnormal events in real-time.

This newsletter provides a concise overview of the new features introduced in our latest software...

Our office in Lyngby, Denmark (by DTU) is enjoying the internship with Mercedes Belda Ley from...

The high level theme for the release is how we ensure coverage of failure modes. Kairos functional...

Kairos Technology is a software company that develops innovative and disruptive technology within the energy industry.

Phone: +47 952 91 478

E-mail: info(a)kairostech.no

Address Norway:

Kanalsletta 4, N-4033 Stavanger

Address Denmark:

DTU Science Park, Diplomvej 381, DK-2800 Lyngby