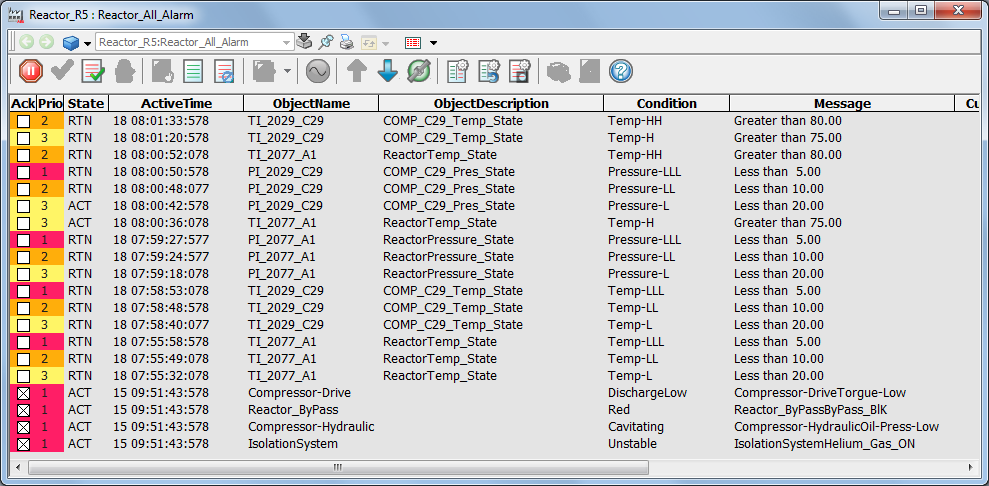

An alarm list from ABB 800xA alarm management system

How can you know if your alarms are giving you a problem? There are different indicators that can be seen when we are experiencing alarm problems, and they usually show up in the alarm system.

So what is an alarm system?

An alarm system is a basic operator support system for managing abnormal situations, by warning the operator about not normal conditions and provide historical data in the form of an alarm and event log.

The warning helps attract the attention of the operator so that they can control the future behaviour of the process, while the logs provide data used to analyse the events that have caused abnormal situations.

An alarm system provides precise and useful information and functionality to support the operator's tasks. A correctly designed alarm system should provide information in a way that is easily understandable, considering human capabilities and limitations. The system should inform the operator about plant conditions that require timely assessment and possibly corrective action, in order to maintain plant goals in terms of safety, productivity, environment, and efficiency.

Are my operators having an alarm problem?

At a glance it looks like an absurd question, but the operators do suffer from alarm problems if the alarm system is not designed correctly. The alarm problem reduces their effectivity in analysing the abnormal situations, and their capabilities to take timely corrective actions that avoids an escalation of abnormality, resulting in production loss or a safety incident.

Let's look at few scenarios –

- If the operator receives hundreds of alarms before an emergency shutdown situation, their capabilities are reduced when taking corrective actions. If the alarm log is filled with a thousand alarms after an emergency shutdown, it is difficult to analyse the log in order to improve operator actions and to avoid similar situations.

- Nuisance alarms, and chattering alarms causes stress to the operator, thereby reducing their attention towards real alarms.

- Incorrect text or description of alarms adds stress in day-to-day operations.

- It's very common during commissioning and start-up to add new alarms or set higher/lower priorities on alarms. However, this causes extra stress, reduced attentivity, and possibly ignorance from operators.

Above and other similar scenarios can cause fatigue and latency in operator’s actions and reduce their ability to respond to the abnormal situations. This means that your alarm system is not effectively designed and that your operators are experiencing alarm problems.

How can we resolve alarm problems?

Alarm rationalization and alarm management both help resolve the alarm problems.

Alarm rationalization is a process of reviewing, validating and justifying each configured alarm and its parameters. Alarm philosophy and specifications developed based on various alarm standards and site-specific requirements become the basis for alarm rationalization.

Continuous alarm management helps identify how an alarm system is performing through KPI metrics and reports. Alarm standards define various KPI metrics and suggest their threshold values. Thresholds can vary based on company or site requirements. The KPIs provide necessary metrics for analysis and operations can take necessary corrective actions in order to improve performance of the alarm system. KPIs also help provide information that can form the basis for alarm rationalisation.

Various software tools are available to execute continuous alarm management through KPI reporting, with standard and advanced functions to help reduce the alarm problem.

In conclusion:

Use alarm management tools to see how your alarm system is performing. If you conclude that you have an alarm problem, then with the help of these tools and alarm management standards, along with focused approach from operators and operations management, you can reduce or eliminate the alarm problem.

An efficient alarm system will help operators perform their work with high attention and efficiency, and it creates an environment for safe and productive plants.