4 Benefits of having a service agreement for your alarm system

Without proper maintenance alarm systems can deteriorate and become less effective. A healthy alarm system is needed to avoid escalation of hazards.

Maintaining your alarm system can help prevent accidents and loss in production. It ensures a healthy alarm system, which is more cost efficient than having larger alarm rationalisation projects at irregular intervals.

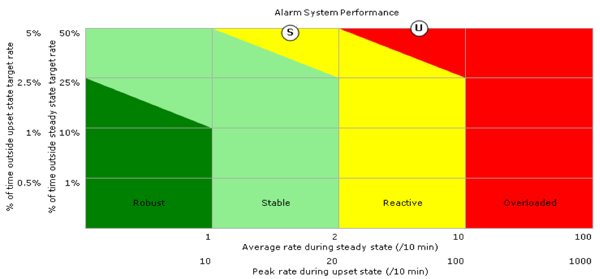

According to alarm standards and guidelines, an operator must have enough time to detect an alarm, diagnose the situation, respond with corrective action(s), and monitor the condition, then verify that the abnormal condition has been corrected. The operator should be able to handle the announced alarms in this described way in a steady state of operation.

In order to have the ability to do this, the operator cannot handle more than 1-2 alarms during a 10-minute period.

Figure 1. EEMUA 191 Alarm analysis summary monthly report (S=Steady state, U=Upset state)

When the alarm load goes from robust to stable, the operator spends more time on alarms. When the alarm load reaches reactive or goes into overload, the operator loses track of the prioritisation of activities. If the plant is in overload condition the operator loses confidence in the alarm system and will be more likely to make mistakes. By using an alarm management system we can make sure that the alarm load is stable and at a rate that the operator can work with.

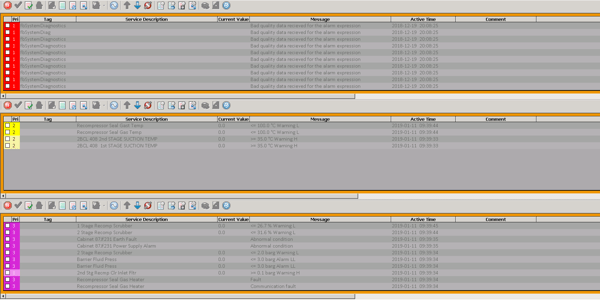

A successful maintenance procedure includes a description of the ownership of the alarm system. The main objective of the maintenance procedure is to ensure that the load to the operator with respect to alarms is at an acceptable level. The key to alarm maintenance is systematic monitoring with quick remediation of problems. The systematic monitoring of alarm performance is simplified by establishing clear KPI’s and monitor these on a weekly or monthly basis. This can easily be done by analysing alarm lists by alarm specialists or by using an alarm management system. The report from the alarm service or the alarm system tool will give you an overview of the alarm load for the operator and how much time it takes for the operator to get back to normal operation after an abnormal condition.

You can use the report from the alarm management system to get the top 10 alarms and to investigate why these alarms are in the top 10 list. Are the alarms activated due to...

Then you should take actions to solve the noise from these alarms.

The 10 most frequent alarms (bad actors) should be followed up weekly. Taking action based on these bad actors will be an advantage in getting the alarm load to a level where the system is usable for the operator.

Example of an alarm list for Pri. 1-3

Example of an alarm list for Pri. 1-3

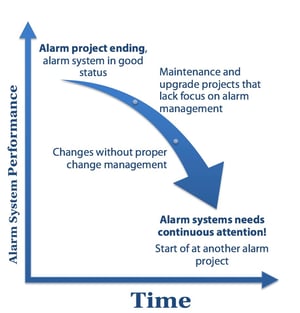

The maintenance of the alarm system is an ongoing activity. There is no reason to take a break from the maintenance of the alarm system during alarm projects.

The savings of doing systematic maintenance of the alarm system is:

The maintenance of the alarm system is an ongoing activity. There is no reason to take a break from the maintenance of the alarm system during alarm projects. Some companies choose to get help from specialists by buying alarm services, while others choose to do most of this work themselves and use alarm management tools to analyse the alarm systems. These tools are powerful, and you will need training to be able to use them to their full potential, which often gives you much more functionality. However, this can be a costly solution, especially if you don’t use the full potential of the tool.

If you don’t have access to an alarm specialist in your own organisation, you can buy an alarm service that takes care of the alarm system performance. This includes weekly or monthly reports, which lists repeating alarms, standing alarms, and more as well as recommended solutions and improvement suggestions.

The consequences of not maintaining the alarms is that you will have too many alarms presented in the alarm system within a specified time period. The operator will be unable to respond to alarms in a structured and safe way during an alarm flood. This can in turn lead to mistakes, damage to people and assets and in worst case lead to shutdown of the facility, all of which are costly consequences.

To conclude: alarm maintenance is not only important, but necessary in order to maintain an alarm system and make sure that the alarm management lifecycle is continuous. This includes a periodic review of key parameters against the alarm philosophy.

Optimised alarms ensure optimised decisions!

Without proper maintenance alarm systems can deteriorate and become less effective. A healthy alarm system is needed to avoid escalation of hazards.

We also know that Alarm System Improvement Projects are complicated. How can we estimate the cost of these improvement projects?

An Alarm Philosophy has to follow specific standards, and you could be held accountable for not applying the standards to your alarm system design.